The Death of the U.S. Penny: Is it Going to Happen?

There has been a lot of talk over the years about the American cent. Much of this talk has orbited around the possibility of the

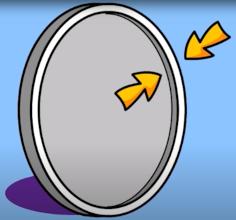

Almost as fascinating and interesting as the coins themselves is the process with which coins are made. The United States Mint has been making coins for currency for two centuries. The Mint has been in operation since 1792, and has been supplying our country with coin currency for the duration. There is a specific process for minting our coins, and though the tools used and some of the techniques applied have changed, the basic process for making coins has stayed the same.

The U.S. Mint has been one of the most stable and lasting institutions in the United States. The Mint has been a hallmark of the United States, and has given the nation steady and consistent service for two-hundred and twenty-five years now. Detailed below is a glimpse at the process that the Mint uses when making their coins:

If you would like to see all of these activities in motion, this YouTube video shows the processes in detail.

The entire process to make a coin might at first sound difficult and time consuming, but it is not. Remember, the U.S. Mint has been in operation for over two-hundred years, and they have streamlined a process that is quite easy to follow along with and is quite effective and beneficial. The process for making coins does involve multiple different steps but it is not a complicated or all too confusing system. The U.S. Mint is able to churn out millions of coins every day, and if an area of the process breaks down such as a press becoming dysfunctional or an annealing oven going out of commission, the Mint has backups to use in such an instance.

More information about the U.S. Mint can be found here.

Knowing the history of how our coins are made is a part of the fun for coin collectors. Coin collecting isn’t just about the coins themselves; it’s something more than that. Here-in lies a hobby that embodies history and American culture. There is more meaning to it than simply acquiring the coins themselves. The feeling and the purpose behind coin collecting embodies a deep-seated enjoyment for the coins themselves, the history of the United States, and the culture of our people.

US Mint – Coin Term Glossary

https://www.usmint.gov/learn/collecting-basics/glossary

US Mint – Coin Production

https://www.usmint.gov/learn/history/coin-production

US Mint – How Coins Are Made …For Kids (video)

https://www.usmint.gov/learn/kids/videos

The Spruce Crafts – How Are Coins Made?

https://www.thesprucecrafts.com/how-are-coins-made-4589253

CoinNews.net – U.S. Mint at San Francisco, Preparing Coin Blanks

https://www.coinnews.net/2013/04/03/u-s-mint-at-san-francisco-preparing-coin-blanks/

YouTube – Making money at the mint in Philadelphia

https://www.youtube.com/watch?v=S56xjC4WCg

There has been a lot of talk over the years about the American cent. Much of this talk has orbited around the possibility of the

Start Collecting Coins It’s easy to start a coin collection. You can begin with coins that you already have on hand. Take your coins out

How Does One Begin Coin Grading? The purpose of this article is to give you enough information so that you can have an idea how

The easiest way to get in contact with us is by filling out the form and submitting it.

We will contact you as soon as we can.

David Enders

PO Box 508

Athens MI 49011

The Dave’s Collectible Coins customer service goal is simple:

We are committed to providing our customers total satisfaction. Every time. Guaranteed.

For non-urgent matters please use the form in this popup. For urgent matters please call 269-742-4716.

Customer service is available Monday – Friday 8:00am – 4:30pm EST